A rotator is a handy device used in ham radio communication systems to change the orientation of an antenna. Rotators have two parts, the rotator unit and the controller. The controller is normally placed near the radio equipment, while the rotator is mounted on the antenna mast below the antenna. It’s a must-have for DXers and operators who want to extend their reach and improve reception.

Is it Rotator or Rotor?

Let’s settle this before we move on. Hams tend to use both words interchangeably, but there is a subtle difference.

- A rotator is a device, such as a motor, that makes something rotate—like a mast with a Yagi attached.

- A rotor is a part of a device that rotates, such as a brake rotor or armature.

How Does an Antenna Rotator Work?

The rotator is typically mounted on the antenna mast or inside the tower, directly below the antenna, while the controller is usually placed in the ham shack near the operator’s position. The controller sends signals to the rotator unit, instructing it to rotate to a chosen heading.

Modern rotators are generally small. Due to gear reduction, the motor mechanism can be relatively compact and not draw much current. Large rotators have bigger motors, but the increase in strength is mostly due to improved gear and brake systems. The power required to turn even those big, stacked arrays is not that much.

To keep rotators from twisting in the wind, they include a braking mechanism. Smaller ones use a friction disc arrangement—when the rotator turns, the discs move apart to let the mast turn freely. When power is removed, the discs clamp together again. With medium-sized rotators, brakes consist of a heavy-duty solenoid with a spring-loaded wedge or bar that fits into indentations inside the rotating housing. On big rotators, worm gears are used and braking is done by the resistance to the gears turning backward under load.

Rotators are designed to turn a full 360 degrees, and often a bit more. That is known as overlap. At the ends of rotation, mechanical limit switches open to remove power from the motor. It’s important to leave a rotator loop in your feedline during installation to prevent stretching or breaking your feedline.

Choosing the Best Antenna Rotator

Durability is important, especially for something that’s exposed to the elements. Look for sturdy materials which can endure outdoor conditions without corroding or deteriorating over time. Opt for models with a sealed housing to protect internal components from moisture and dust for long-term reliability and performance.

Make sure the rotator you choose is compatible with your specific setup. This includes assessing antenna size, weight, and mounting considerations. There’s nothing more annoying than finding that your rotator won’t fit properly inside your tower. Also verify compatibility with any existing hardware you plan to use, such as controllers, accessories, and mountings.

It’s important not to overload a rotator. If you live in a location that’s subject to high winds, continuous winds, or large gusts, look at the wind load recommendations included with the unit. These are usually specified as a maximum antenna area in square feet or square meters. Add all of their wind load numbers together for several antennas on a single mast, and don’t forget the mast’s wind load. You can find your antenna’s specs in the manual or online.

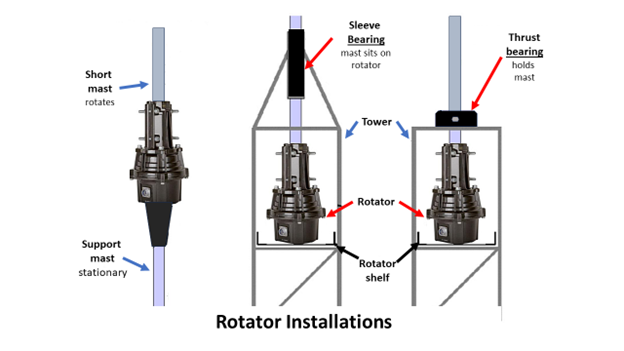

A rotator can handle a larger wind load when mounted inside a tower section, as opposed to mast mounting, since the tower holds the mast in place straight above the rotator. Using a thrust bearing keeps most of the load off the mast, further increasing wind load capabilities. Inside tower mounting eliminates any sideways load on the rotating assembly relative to the base.

In the preferred tower-mounting configuration, a sleeve bearing provides additional support. Another option is using a thrust bearing at the top, which transfers the weight of the antenna and mast onto the tower and off the rotator. The rotator then just turns the antenna without the extra load.

Controlling the Rotator

Each manufacturer of rotator/controller combinations has its own design of control boxes for controlling the rotator and displaying antenna position. Yaesu’s desktop controllers provide a round dial with a 360-degree radial indication of antenna azimuth bearing. Hy-Gain HAM-IV and CD-45II models include a more traditional analog meter readout with N/S/E/W markings and azimuth readings in five degree increments.

There are also aftermarket control units that operate with many different rotators. These include the Green Heron RT-21 Series Digital Controllers and the EA4TX ARS-USB Rotator Controller with digital readout. The coolest of the group is the microHAM ARCO Advanced Rotator Controller (below) with touchscreen LCD control and azimuth information superimposed on a world map display.

If you’re old school, you may want to control your rotator manually with the clockwise/counterclockwise buttons or do point-and-shoot using the preset dial. If you plug in the call sign of a station, most logging programs will provide you with the short path and long path settings you’ll need.

Newer rotator controllers may have an interface—either RS-232 or USB. Some controllers can be connected directly to your PC to operate your unit. Older controllers may require an additional interface board that can be installed inside the rotator control box. For example, programs like PstRotator and DX-Lab can directly calculate the beam direction for long and short path and pass it on to the rotator control. Many of the popular logging software programs can also control a rotator with the help of a PC. The Ham Radio Deluxe Software suite for Windows includes the HRD Rotator Control module, which manages beam headings via any computer-interfaced rotator controller.

Interested in space? An antenna rotator with both rotational and elevation controls, like the Yaesu G-5500DC (plus related software), is essential for ham radio satellite, ISS, and EME (moonbounce) communication. It enables users to accurately track satellites and the ISS as they move across the sky. Such equipment can make adjustments quickly, maintaining a solid connection for communication.

What’s Right for You?

Decide what antenna(s) you plan to put on your mast or tower and calculate the total wind load. It doesn’t hurt to go a bit larger on your rotator. You’ll have some additional headroom and prepare for the possibility of an antenna upgrade or added antenna later on. It’s difficult to change out rotators on a tower—I know from experience.

Rotator packages usually include the necessary connectors. You’ll need to supply the wiring between the controller and the rotator, usually a six- or eight-conductor for ham rotators and three- or four-conductor for TV/light-duty rotators. They can be purchased by the foot or as ready-made cables. Other items to consider include thrust bearings and rotator shelves inside tower mounts, like the DX Engineering Accessory Shelf below for Yaesu and Hy-Gain rotators.

Light-Duty Rotators

For smaller VHF/UHF Yagis and rotatable dipoles with wind loads >3 sq. ft. Mast/inside tower mount.

- Hy-Gain AR-40, AR-500

Medium-Duty Rotators

For Hexbeam, tri-band 3-element monoband Yagis, and larger VHF/UHF arrays with wind loads of 8-10 sq. ft. Inside tower mount.

Medium/Heavy-Duty Rotators

For multi-element Yagis with wind loads of 15-22 sq. ft. Inside tower mount.

Heavy-Duty Rotators

For large Yagis, multiple Yagis with wind loads to 35+ sq. ft. Inside tower mount.

Editor’s note: The DX Engineering RT4500HD rotator comes in combos which include rotator and 2-inch or 3-inch mast clamp; rotator, clamp, and ARCO controller (below); and rotator, clamp, and DX Engineering controller.