No two Amateur Radio stations are the same, so buying an “off the shelf” coaxial cable assembly usually means dealing with several feet of extra, unwanted cable. Not only does that clutter up your Ham shack, sending your signal through excess coax cable also has a negative affect on station performance. DX Engineering has just introduced a Custom Cable Builder that allows you to build a precise cable assembly tailored to your unique setup. You select the cable type, its length, and the connectors you want.

In addition to improved performance and a cleaner shack, the Custom Cable Builder will save you money, since you’re only buying the exact length of cable you need to complete your coax runs. You can also use this tool to build custom copper braid (strap) assemblies to create a one-off grounding system. Using the Custom Cable Builder is a no-cost service; you only pay for the cable and connectors used to make your new cable.

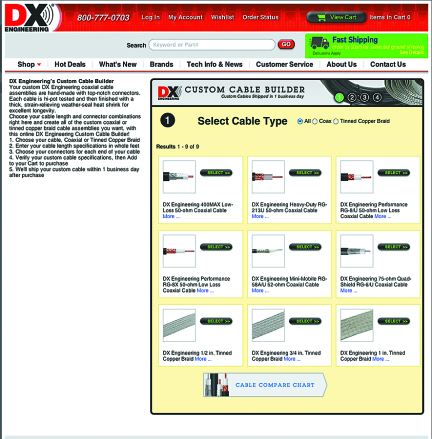

Here’s how it works:

1) Select the DX Engineering cable you want to use. This includes RG-231, RG-8X, RG-8U, 400MAX, RG-6 or copper ground braid. During this step, you’ll also enter the length of your new cable.

2) Choose the connectors you want on each end, e.g. PL-259, BNC, Type N or Type F, in both male and female configurations. You may also select one or both ends to terminate without a connector. Depending on the cable type you select, mix and matching connectors is OK too. For example, you can have a PL-259 on one end and a Type N connector on the other. If you’re building a ground braid strap, then your connector choices will consist of standard ring terminals (lugs) in #10, 3/8″ or 1/4″ sizes.

3) Once you’ve got your specs filled out, click “Add to Cart” and you’re done. DX Engineering’s techs will then build your custom cable assemblies. Each new cable endures rigorous hi-pot testing before it leaves the DX Engineering facility. In most cases, you’ll get your custom cable assemblies in just a few days.